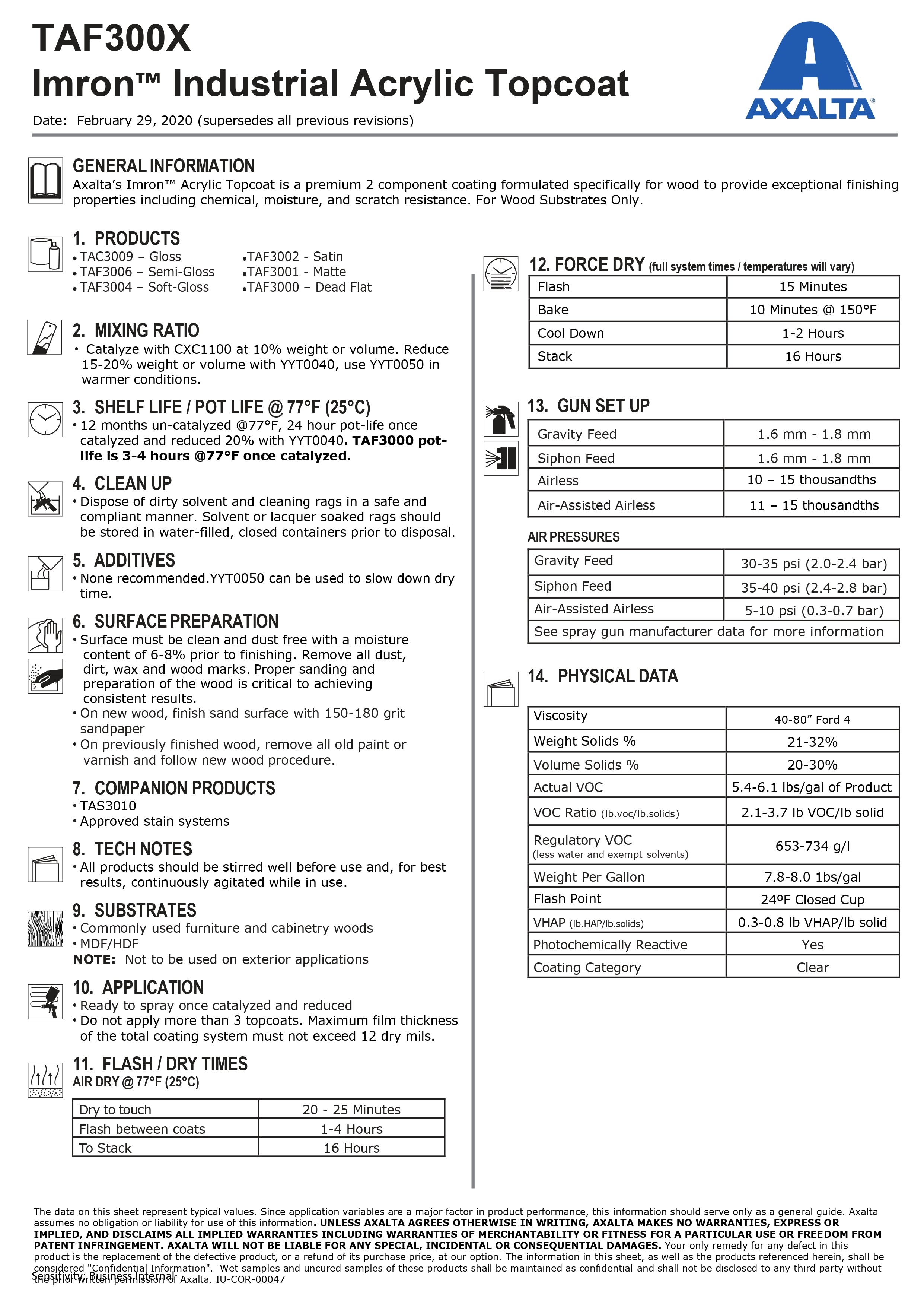

- Home / Finish Specifications

Acrylic Urethane Finishes

Italian Coatings Technology Exceptional Performance

Performance Features

- Ultra low formaldehyde

- Almost no oder after finishing - no burning eyes

- Excellent chemical, moisture and scratch resistance

- Passed Kitchen Cabinet Manufacturer’s Assoc. testing

- Will not break down or get soft after years of heavy use

Further Performance Testing

(All resulting in no change to finish)

- Water held on oak sample for 5 days

- 400 deg. F cooking pan on sample for 5 min.

- 1 hour in 150 deg. F followed by -50 deg. F (8 cycles)

- Accelerated UV testing: no fade @ 10 yr equivalent

- 4 hour chemical resistance test: vinegar, lemon

juice, grape juice, orange juice, ketchup, coffee, olive

oil, and 100 proof alcohol